-

AuthorPosts

-

October 6, 2008 at 10:24 am #44941

Karl Crooks

MemberPolitefab thanks for the photos !

I really like the radius in the corner, as a company that specializes in repair, we have seen many cracks start at that corner. The radius in the corner should help to eliminate cracking at that point. It looks like you have a great system there !

October 6, 2008 at 10:31 am #44943Eli Polite

Memberits been well thought out having a background in solid surface has help in a lot of my methods. if you want one let me know

i cut it close and than back bevel the bottom side if the seam and go over it with a 100 grit z bit to remove all the chips and give me a near perfect seam

October 6, 2008 at 10:32 am #44944Eli Polite

Memberi have sold quite a few already and will be demonstrating it at expo in vegas

October 7, 2008 at 5:39 pm #45057Kevin Padden

MemberVery cool Eli !!!

I actually have a variant of the same thing that I am rolling out for students that come to the AZ School of Rock…

Are you making the jig out of an HDPE product or some other kind of plastic?

Very Nice!!!!

kevin

October 7, 2008 at 9:39 pm #45066Eli Polite

Member100% solid surface http://thefabricatornetwork.com/DesktopModules/NTForums/themes/fabnet/emoticons/biggrin.gif

i have sold many of them and get many requests i have had a great response. if it is used correctly it will last for ever i have been using the same one for over a year now with great results

October 7, 2008 at 10:00 pm #45068Norm Walters

MemberEli, what kind of browser are you using that turns a smiley into HTML text?

October 8, 2008 at 1:24 am #45072Andy Graves

KeymasterEli,

What type of tooling do you use to follow the template?

October 8, 2008 at 4:41 pm #45119Eli Polite

Memberi was on my mac . now im on my dell ……

ill post more pics with the tooling i use

October 9, 2008 at 4:10 pm #45177Eli Polite

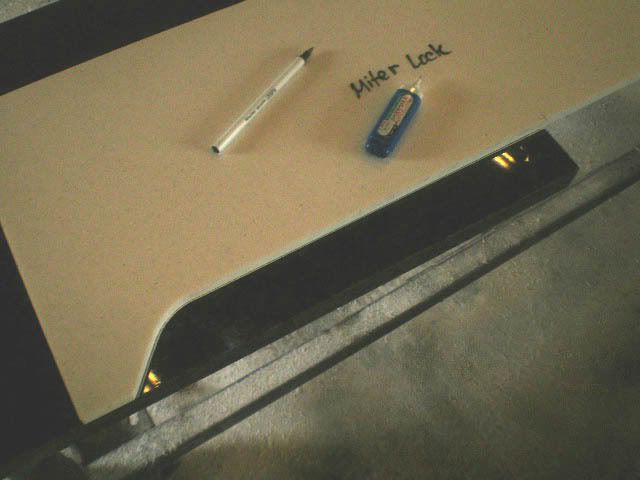

Memberi mark what i am going to cut. in most cases i just make this cut on the beam saw but it can be cut by hand. i cut it about 1/8″ away from my marked lines

once it is cut close i clamp my template back on and get out my galesky. i first back bevel the seam and use a 100 grit z bit to finish the seam off. some times if i did not cut it quite close enough to the template i use a 30 grit z wheel first

October 9, 2008 at 4:15 pm #45179Eli Polite

Memberi use the same thing for the mail side of the miter lock

if you decide to go to the expo stop in before 10 am ill be demoing it at the SFA booth thursday and friday

October 15, 2013 at 11:22 am #76501sdrockslangers

MemberDo you still sell this template for the inside corner seams. If so is there any special tools that should be used to get maxium results.

Steve Vasquez 916 247 0623

-

AuthorPosts

- You must be logged in to reply to this topic.