Custom Solid Surface Sink Fabrication

Last week I worked with a lady that wanted a nontraditional vanity sink. Using her ideas I provided her with a concept of what I thought she wanted. Once she approved I began building.

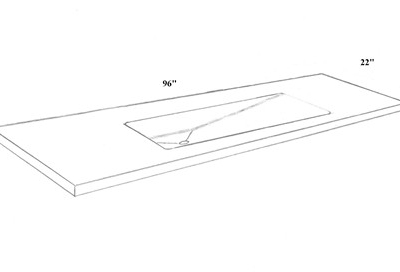

Pencil sketch for approval.

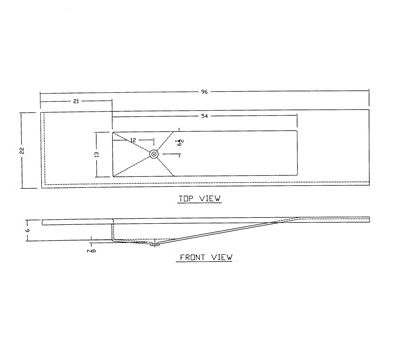

Detail drawing for confirming measurements.

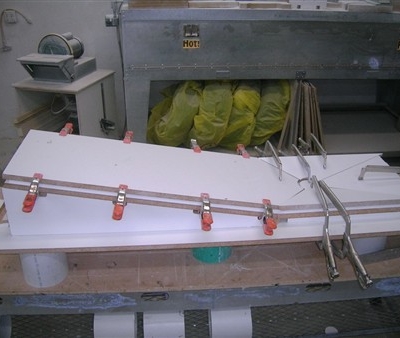

Form for thermoforming the bottom of the basin.

Material clamped in form

After the bottom cooled I routed the rabbet for the cove build up strip.

This shows better the slope of the bottom and the rabbet. The bottom is slightly over sized and will be trimmed after the sides are attached.

Cove build-ups are glued into rabbets in the side pieces and then pre coved. The front and back of the basin are rabbeted to accept the pre-assembled and coved end panel. Here they are set up for dry fitting.

I used a bridge router set up to trip the top of the sink to a flat plane.

Tile backsplash with a full-width mirror will be installed by the contractor.

The really weird thing was that the contractor said that the inspector was going to insist on an overflow. I told him that this was a custom sink and that he should make a case for not having an overflow since most vessel sinks are not designed with one. Dupont now offers a line of their vanity sinks without overflows. Kitchen sinks seldom (almost never) have an overflow. All that combined with the fact that this sink holds so much water that the chance of it ever being filled up is slim to none.

It has been a week and I have not gotten a call back yet.

Johnny C

For more information about Johnny’s Company, please visit – www.facebook.com/SolidSurfaceTechnologies